A progressive cavity pump has a steel rotor with a spiral shape. The rotor turns inside a rubber stator with two spirals. People may call it a progressing cavity pump, eccentric screw pump, or mono pump. When the rotor spins, it makes closed spaces that move liquid forward. This type of pump is special because it can handle thick, rough, or delicate fluids. It also keeps the flow steady with almost no stops or jumps. Many industries use progressing cavity pumps. If you need to move thick or chunky liquids, this pump gives you steady flow and works well.

Key Takeaways

A progressive cavity pump has a spiral rotor inside a soft stator. It moves liquids in a smooth and steady way. This pump can handle thick, rough, or gentle liquids. It does not hurt the liquids. The flow stays the same even if pressure changes. It works well for hard jobs in places like wastewater, food, oil, and chemicals. It can move liquids with solids or bubbles. The pump should never run without liquid. The liquid cools and oils its parts. Doing regular checks helps the pump last longer. This pump gives gentle flow and high pressure. It needs more care than other pumps. It may also cost more at first.

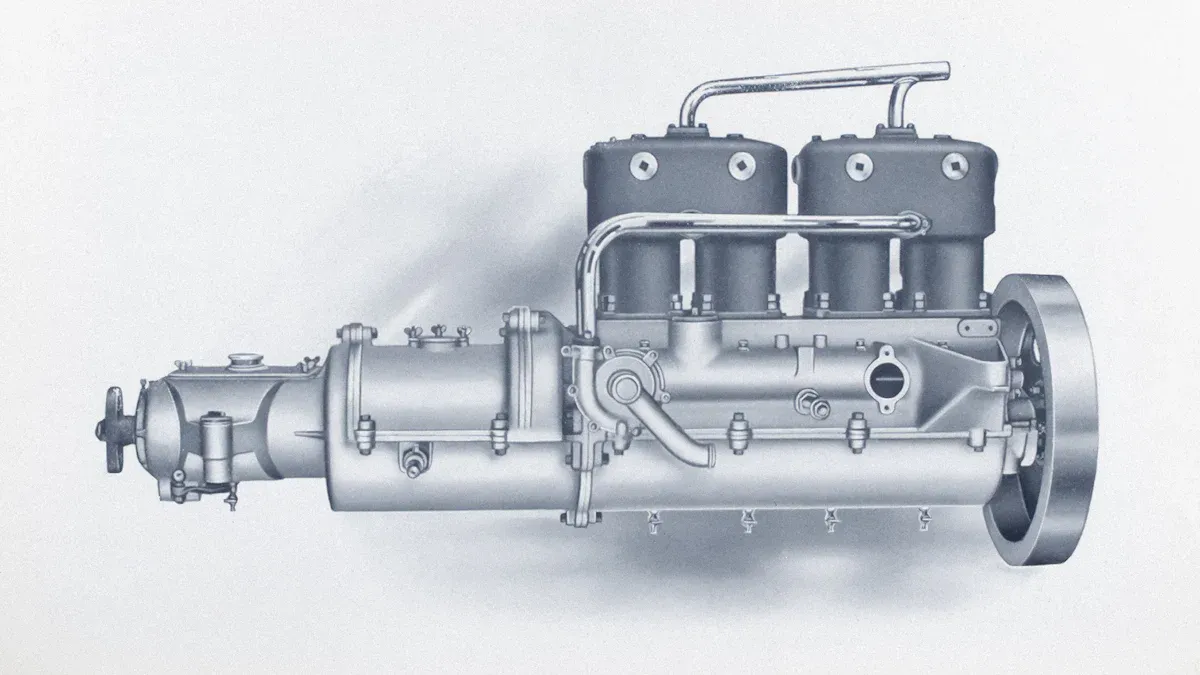

Progressive Cavity Pump Components

![Progressive Cavity Pump Components Progressive Cavity Pump Components]()

Progressing cavity pumps have several main parts that work together to move fluids. Each part has a special job. You can see the main components and their functions in the table below:

Component | Function |

Rotor | Helical screw that rotates to move liquid from inlet to outlet. |

Stator | Elastic, rubber-like sleeve that forms a tight seal around the rotor. |

Housing | Outer shell that protects the inside parts and guides the fluid. |

Drive Unit | Motor or hydraulic system that turns the rotor. |

Rotor

You will find the rotor at the heart of progressing cavity pumps. It looks like a metal screw with a spiral shape. When the drive unit turns it, the rotor spins inside the stator. This action creates small, sealed spaces that push the fluid forward. The helical design helps the pump handle thick, gritty, or delicate fluids without breaking them apart.

Stator

The stator surrounds the rotor. It is usually made from a flexible, rubber-like material. The stator has its own spiral shape, but it has one more twist than the rotor. This design lets the rotor and stator form tight, moving cavities. These cavities carry the fluid smoothly through the pump. The elastic stator also helps stop leaks and keeps the flow steady.

Tip: The stator and rotor need fluid to stay cool and avoid damage. Never run progressing cavity pumps dry.

Housing

The housing covers the rotor and stator. It keeps everything in place and protects the pump from outside damage. The housing also directs the fluid into and out of the pump. Some progressing cavity pumps have special housings for tough fluids or high pressures.

Drive Unit

The drive unit gives power to the pump. Most progressing cavity pumps use an electric motor, but some use hydraulic systems. The drive unit connects to the rotor and makes it spin. Without this part, the pump cannot move any fluid.

Key points about progressing cavity pumps:

The rotor and stator work together to create sealed cavities.

The elastic stator ensures a tight seal and smooth flow.

Fluid lubrication is important for long pump life.

Progressing cavity pumps use these parts to deliver steady, gentle flow for many types of fluids. You can rely on them for thick, abrasive, or sensitive liquids.

How It Works

Pumping Principle

You see the positive displacement principle at work in every progressive cavity pump. This principle means the pump moves a fixed amount of fluid each time the rotor turns. The rotor sits inside the stator and forms tight, moving cavities. As the rotor spins, these cavities expand on the suction side and shrink on the discharge side. This action pulls fluid in and pushes it out. The pump keeps the flow steady, even if the pressure changes. You get a constant flow at a set speed, which sets progressing cavity pumps apart from centrifugal pumps.

A progressive cavity pump uses a helical rotor inside a rubber-lined stator. The rotor turns in an offset way, creating spaces that trap and move fluid. These spaces, or cavities, travel from the inlet to the outlet. The pump can handle thick, gritty, or delicate fluids because it keeps pressure stable and flow smooth. This is the main function of progressing cavity pumps.

Fluid Movement

The rotor and stator work together to move fluid gently. Here is how the process happens step by step:

The rotor, shaped like a screw, starts to turn inside the stator.

This turning creates sealed cavities at the pump's inlet.

The cavities move along the pump as the rotor keeps spinning.

The fluid inside each cavity travels forward, pushed by the rotor's motion.

Near the outlet, the cavities get smaller, which raises the fluid's pressure.

The fluid leaves the pump in a steady stream.

You notice that progressing cavity pumps do not create sudden bursts or stops. The flow stays smooth and even. The tight seal between the rotor and stator stops backflow. This design means you get low pulsation and a constant flow, even if the pressure changes. Many industries choose progressing cavity pumps for this reason.

Note: The gentle movement protects sensitive fluids. You do not have to worry about breaking or damaging the product.

Sealing and Flow

The sealing lines between the rotor and stator keep the fluid inside the cavities. These lines form as the rotor and stator mesh together. The stator's flexible material helps it match the rotor's shape. This match keeps the cavities sealed as they move. The pump controls slippage, which is when a small amount of fluid leaks between cavities. The balance between pressure and fluid thickness affects how much slippage happens.

Fluid lubrication is very important for the pump. The fluid you move also cools and protects the rotor and stator. If you run the pump dry, the parts can wear out fast. Always make sure fluid is present before starting the pump. Regular checks and proper lubrication help your pump last longer and work better.

Tip: Never run progressing cavity pumps dry. Always follow the manufacturer's advice for lubrication and maintenance.

You can rely on progressing cavity pumps for steady, gentle, and reliable fluid transfer. The unique design lets you move thick, abrasive, or sensitive fluids without trouble. The pump's ability to keep a constant flow and low pulsation makes it a top choice for many tough jobs.

Pros and Cons

Advantages

There are many good things about using a progressive cavity pump. This pump works well for hard jobs. It is great for moving thick fluids or slurries. Here are some main advantages of these pumps:

You can move thick fluids, slurries, and mixes with air or gas. Some pumps work with fluids that have up to 50% gas. They do not lose power.

The pump moves delicate fluids gently. It can move soft solids without breaking them. For example, a cosmetics company made better lotion and wasted less after using this pump.

You get steady results with fluids of different thickness. A chemical plant moved thick resin and did not have clogs.

The pump can start on its own. You do not need extra tools to begin pumping. A food plant pumped syrup easily because of this.

You can measure fluids exactly. The pump gives a steady flow with little pulsing. This helps when adding ingredients. A drug company used it to add the right amount.

The pump is quiet. Hospitals and places that need less noise like this.

You can pick from many types and materials. This helps you choose the right pump for your job, like using parts that do not rust for acids.

The pump does not wear out fast. Wastewater plants use it to move sludge with sand and grit. This makes the pump last longer.

Tip: The pump's gentle flow and self-starting help protect your product and equipment.

Disadvantages

You should know the bad sides before picking this pump. Some problems may change your work or cost more money.

The pump cannot run without fluid. If it does, the stator gets too hot and wears out fast. Running dry can break the pump before sensors stop it.

The stator and rotor can wear out faster with rough fluids. You may need to change parts more often.

Fixing the pump can be harder and needed more often than other pumps. Special parts and tools can cost more.

The pump costs more at first than some other pumps. But new designs can save money over time.

The pump moves less fluid and does not self-start as well as twin-screw pumps.

It needs more power to start, which can stress your power system.

The pump does not move fluids with lots of solids as well as rotary lobe pumps. Long, stringy solids can clog it or make it work less well.

Aspect | Progressive Cavity Pump | Rotary Lobe Pump |

High Viscosity Fluids | Excellent | Good |

Abrasive Fluids | Faster wear | Better resistance |

Self-Priming | Yes | Yes |

Maintenance | More frequent, costly | Lower, easier |

Solid Content Handling | Limited | Excellent |

Note: Always check fluid levels and do regular maintenance to keep your pump working well.

Progressing Cavity Pumps: Applications

Progressing cavity pumps are used in many jobs. These pumps move thick, rough, or gentle fluids. Other pumps may not work as well for these fluids. Many industries use progressing cavity pumps. The table below lists some common uses:

Industry | Common Applications |

Wastewater | Sludge, slurry, high solids wastewater, chemical feed |

Food & Beverage | Thickened foods, beverages, sanitary pumping, pharmaceuticals |

Oil & Gas | Crude oil transfer, artificial lift, drilling mud, multiphase fluids |

Chemicals | Adhesives, paints, detergents, liquid chemicals |

Wastewater

Progressing cavity pumps are found in wastewater plants. They move sludge and slurry. These pumps work with thick fluids that have lots of solids. They are good for sewage and cleaning water. The pumps can move rough slurries and sticky stuff without clogging. Some pumps have special hoppers for thick sludge.

Common fluids:

Sludge

Slurry

High solids wastewater

Tip: Always check for fluid before you start the pump. Running dry can break the stator.

Food and Beverage

These pumps help keep food safe and clean. You can use them for sauces, yogurt, fruit puree, and drinks. The pumps use stainless steel and smooth rubber stators. They are easy to clean and do not mix in dirt. Some pumps let you clean them without taking them apart. They move soft foods gently, so the food stays good.

Features:

Oil and Gas

You see these pumps in oil fields and refineries. They lift oil from wells and send it to tanks. The pumps move thick, rough, and mixed fluids. They give a steady flow and protect machines. Some pumps have smart controls to watch them work. They also move drilling mud and water from oil wells.

Uses:

Lifting oil

Moving crude oil

Pumping drilling mud

Chemicals and Industry

These pumps move chemicals, glue, paint, and soap. They can handle liquids with different thickness and solids. The pumps do not rust or wear out fast. Some have screw feeders for pastes or hoppers for sticky stuff. You can use them in mining, paper mills, and power plants.

Note: Progressing cavity pumps work well for hard jobs in factories.

Comparison to Other Pumps

Centrifugal Pumps

Centrifugal pumps are common for moving lots of water or thin liquids. These pumps have spinning blades that push fluid out. They work best when you want high flow and low pressure. If you try to pump thick or sticky fluids, they lose power and do not work well. They also make more shear, which can hurt delicate fluids.

Here is a table to help you compare progressive cavity pumps and centrifugal pumps:

Feature | Progressive Cavity Pumps (PC) | Centrifugal Pumps |

Pump Type | Positive displacement, rotary motion | Dynamic, velocity-based |

Flow vs Speed | Flow proportional to speed, steady at any pressure | Flow drops as pressure rises |

Viscosity Handling | Handles thin to very thick fluids, even with solids | Works best with thin fluids, struggles with thick ones |

Efficiency Range | 55% to 75%, stable across pressures and viscosities | Peaks at certain pressure, drops with thick fluids |

Shear on Fluid | Low shear, gentle on fluids | High shear, can damage sensitive fluids |

Self-Priming | Yes, strong suction lift | Needs liquid at inlet, limited suction |

Solids Handling | Moves solids and gas slugs well | Limited, needs special parts for solids |

Tip: If you need to move thick, gritty, or delicate fluids, a progressive cavity pump works better than a centrifugal pump.

Peristaltic Pumps

Peristaltic pumps use rollers to squeeze a hose and move fluid. This design is simple and has no seals, so leaks are rare. These pumps can handle very thick and rough fluids. They can run dry and not get damaged. You can also reverse the flow to clear blockages. Changing the hose is quick and easy.

Here is a table to compare progressive cavity pumps and peristaltic pumps:

Feature / Aspect | Progressive Cavity Pumps | Peristaltic Pumps |

Pumping Mechanism | Rotor and stator, spiral motion | Hose compression, peristaltic action |

Pressure Handling | High pressure, good for slurries | Moderate pressure, best for high solids |

Maintenance | Needs seal care, more complex repairs | Simple hose swaps, low downtime |

Energy Use | Higher, needs fluid for lubrication | Lower, uses less energy |

Self-Priming | Yes | Yes |

Solids Handling | Good, but not for very high solids | Excellent, pumps thick slurries and pastes |

Flow Reversal | Not typical | Yes, easy to reverse |

Note: Peristaltic pumps are best for very thick or dangerous fluids and when you want easy care.

When to Choose

Pick a progressive cavity pump if:

You need to move fluids from thin to very thick, even with solids or bubbles.

You want a steady, gentle flow for sensitive products.

Your job needs high pressure or self-priming.

You must not damage the fluid, like in food, chemicals, or wastewater.

You need to handle rough or stringy materials without clogging.

Choose a centrifugal pump for clean, thin fluids at high flow rates. Pick a peristaltic pump for very thick, rough, or dangerous fluids, or when you want fast, simple care.

Remember: Always match your pump to your fluid's thickness, solids, and needed pressure. This helps you get the best results and makes your pump last longer.

You now know a progressive cavity pump moves fluids gently and steadily. It uses a rotor and stator to push liquid without sudden stops. This works even with thick or gritty mixtures. The pump is quiet and can make high pressure. It also starts by itself without help. Some jobs need these special features. But you must watch for worn parts and never let it run dry.

Key Benefit | Typical Use | Main Limitation |

Smooth, steady flow | Sludge, food, oil | Needs fluid to run |

Handles solids | Chemicals, wastewater | Higher maintenance |

If you need to move tough fluids and want steady flow, a progressive cavity pump is often the best choice.

FAQ

What fluids can you pump with a progressive cavity pump?

You can move thick, thin, gritty, or delicate fluids. It works well for sludge, pastes, oils, chemicals, and food products. You can even pump fluids with small solids or air bubbles.

Can you run a progressive cavity pump dry?

No, you should never run it dry. The pump needs fluid for cooling and lubrication. Running it without fluid can damage the stator and rotor quickly.

How do you maintain a progressive cavity pump?

You should check for leaks, listen for strange noises, and inspect seals often. Replace worn parts as needed. Keep the pump clean and always make sure fluid is present before starting.

What makes a progressive cavity pump different from other pumps?

It gives you a steady, gentle flow. It handles thick or chunky fluids better than most pumps. You get less pulsation and can move sensitive products without damage.

How long does a progressive cavity pump last?

If you maintain it well and avoid running it dry, it can last many years. The life depends on the fluid type and how often you use it. Regular checks help you spot problems early.